-

tel: +86 13012879648

-

email: info@jingyitechno.com

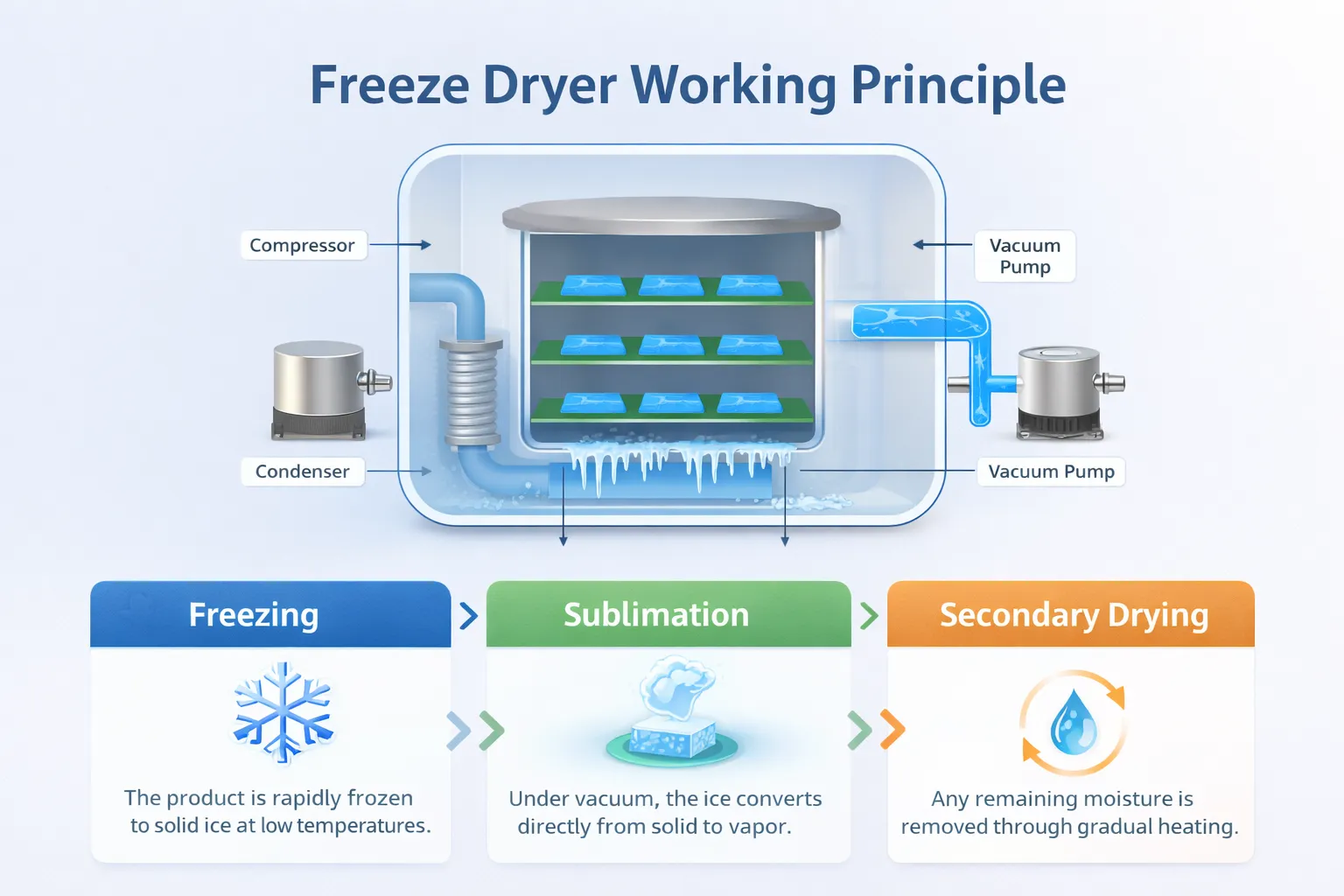

how does a freeze dryer work

Freeze drying, also known as lyophilization, is an advanced dehydration process widely used in the food, pharmaceutical, biotechnology, and chemical industries. Understanding how a freeze dryer works is essential for manufacturers and researchers seeking long shelf life, superior product quality, and maximum nutrient retention.

Quick Answer: How a Freeze Dryer Works

A freeze dryer works by freezing the product and then lowering the pressure so ice sublimates directly into vapor without passing through the liquid phase. This vacuum freeze drying process preserves structure, nutrients, and shelf life far better than conventional drying methods.

This article explains the working principle of a freeze dryer, the complete freeze drying process, and why vacuum freeze drying is critical for commercial and industrial applications.

Common applications include:

· Freeze dried fruit and vegetables

· Pharmaceutical and vaccine lyophilization

· Biological samples and enzymes

· Functional foods and nutraceuticals

How Does a Freeze Dryer Work?

The freeze drying process consists of three core stages: freezing, primary drying (sublimation), and secondary drying (desorption).

1. Freezing Stage

During the freezing stage, the product is cooled below its eutectic or glass transition temperature. This step determines the final product structure. Rapid freezing produces smaller ice crystals, while controlled freezing improves pore structure and drying efficiency.

Key factors:

· Freezing temperature and rate

· Product thickness

· Shelf cooling uniformity

2. Primary Drying (Sublimation)

In the primary drying stage, the freeze dryer creates a high vacuum inside the drying chamber. Heat is gently applied to the shelves, providing the energy required for ice to sublimate directly into water vapor. The vapor is captured by a condenser operating at ultra-low temperatures.

This stage removes up to 95% of the total moisture and is the most energy-intensive phase of the freeze drying process.

3. Secondary Drying (Desorption)

Secondary drying removes unfrozen, bound water molecules. By slightly increasing the product temperature under continued vacuum conditions, residual moisture is reduced to extremely low levels, ensuring long-term stability and shelf life.Typical final moisture content: 1–3%.

Key Components of a Freeze Dryer

commercial freeze dryer consists of several integrated systems:

· Drying chamber with temperature-controlled shelves

· Vacuum system (rotary vane or dry vacuum pumps)

· Condenser (ice trap)

· Refrigeration system

· PLC control system with recipe management

Each component plays a vital role in ensuring consistent and repeatable freeze drying results.

Why Vacuum Freeze Drying Matters

Vacuum freeze drying offers unique advantages over hot air drying or spray drying:

· Preserves cellular structure and appearance

· Retains nutrients, flavors, and bioactive compounds

· Enables rapid rehydration

· Extends shelf life without preservatives

For these reasons, freeze drying technology is widely adopted in high-value food processing and pharmaceutical manufacturing.

Industrial and Commercial Freeze Drying Applications

Modern freeze drying equipment supports:

· Large-scale freeze dried fruit production

· Pharmaceutical GMP-compliant manufacturing

· Laboratory R&D and pilot-scale testing

· Turnkey freeze drying processing lines

Industrial freeze dryers are engineered for continuous operation, energy efficiency, and precise process control.

Choosing the Right Freeze Dryer

When selecting freeze drying equipment, consider:

· Production capacity and batch size

· Product characteristics

· Energy consumption

· Automation and data recording

Working with an experienced freeze dryer manufacturer ensures optimized process design and long-term operational reliability.

About Shanghai Jingyi Tech Co., Ltd.

Shanghai Jingyi Tech Co., Ltd. is a high-tech manufacturer specializing in vacuum freeze drying technology. Since 2007, the company has provided commercial-scale and industrial freeze dryers, along with turnkey vacuum freeze drying processing lines, to customers worldwide.

With three modern manufacturing bases and a dedicated pilot-scale freeze drying laboratory, Jingyi Tech supports food, pharmaceutical, and research clients with equipment design, process validation, installation, and technical training.

Freeze Dryer FAQs

What is the working principle of a freeze dryer?

A freeze dryer works by freezing the product first and then removing moisture without turning the ice into liquid water. Under low pressure, the ice inside the product slowly changes directly into vapor. This helps the material keep its original shape, texture, and quality during drying.

Why does freeze drying require a vacuum?

The vacuum creates a low-pressure environment inside the drying chamber. In these conditions, ice can be removed at low temperatures instead of melting first. This is especially important for heat-sensitive products like fruit, pharmaceuticals, and biological materials, where excess heat can damage structure or activity.

Freeze drying is not a fast process. Most batches take anywhere from 12 to 48 hours. The actual time depends on the product itself, how thick it is, how it is frozen, and the capacity and design of the freeze dryer.

What products are best suited for freeze drying?

Freeze drying is commonly used for fruits and vegetables, instant coffee, meat products, pharmaceuticals, vaccines, enzymes, and other high-value materials. It is especially useful when long shelf life, stable quality, and good rehydration are required.

What is the difference between a freeze dryer and a dehydrator?

A freeze dryer removes moisture under vacuum through sublimation, while a dehydrator uses heated air to evaporate water. Because of this difference, freeze-dried products usually keep more nutrients, maintain their original shape better, and rehydrate faster than products dried with hot air.

For professional consultation on freeze drying equipment and turnkey solutions, contact:

· Email: info@jingyitechno.com

· WhatsApp: +86 13012879648

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

.webp) Swedish

Swedish

Polish

Polish

Basque

Basque

Lao

Lao

Bengali

Bengali

Bulgarian

Bulgarian

.webp)