-

tel: +86 13012879648

-

email: info@jingyitechno.com

Is Instant Coffee Freeze Dried?

Instant coffee is not produced using a single, uniform drying method. In commercial production, both freeze drying and spray drying are used, with freeze drying typically reserved for higher-quality instant coffee products where flavor retention and aroma preservation are critical.

How Freeze-Dried Instant Coffee Is Made

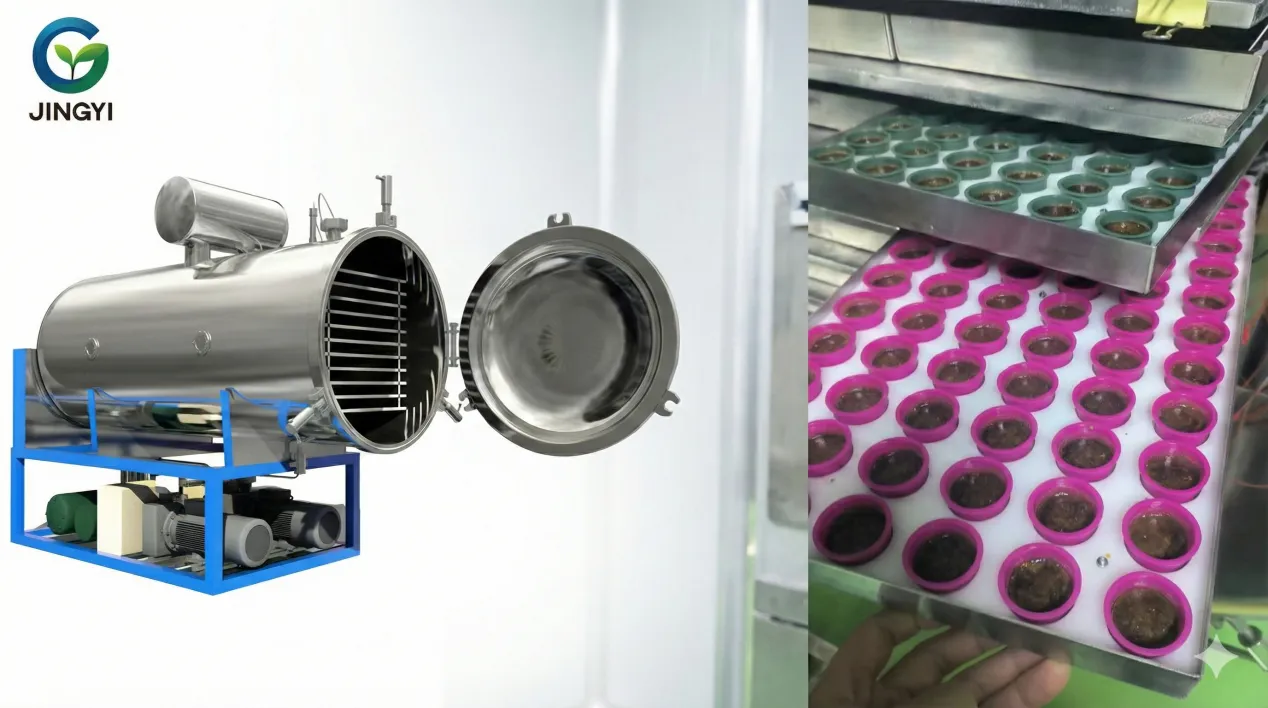

In freeze-dried instant coffee production, brewed coffee extract is first concentrated and then rapidly frozen at low temperatures. The frozen coffee granules are transferred into a vacuum chamber, where pressure is reduced to allow ice crystals to sublimate directly into vapor. This process removes moisture without passing through a liquid phase.

Because drying occurs at low temperature and under vacuum, volatile aroma compounds are largely preserved. The resulting coffee granules are porous, lightweight, and dissolve quickly in water while maintaining a flavor profile closer to freshly brewed coffee.

Customer Case Example: Using our BSFD-60 industrial freeze dryer, capable of handling up to 600 kg per batch, this method has been applied successfully to produce high-quality freeze-dried instant coffee for premium market applications.

Why Some Instant Coffee Uses Freeze Drying

Freeze drying is widely used for premium and specialty instant coffee due to several advantages:

· Better retention of coffee aroma and flavor

· Minimal thermal damage to sensitive compounds

· Improved appearance and uniform granule structure

· Faster and more complete rehydration

These benefits make freeze drying particularly suitable for single-origin, specialty, and high-value instant coffee products intended for export markets or premium retail positioning.

Freeze Drying vs Spray Drying in Instant Coffee Production

Spray drying is another common method used in large-scale instant coffee manufacturing. In this process, liquid coffee extract is atomized into a stream of hot air, causing water to evaporate rapidly.

While spray drying offers higher throughput and lower production costs, it typically results in greater aroma loss and a denser powder structure. As a result, spray-dried instant coffee is more often used in mass-market products where cost efficiency is prioritized over flavor complexity.

|

Aspect |

Freeze Drying |

Spray Drying |

|

Drying temperature |

Low |

High |

|

Aroma retention |

High |

Moderate to low |

|

Product structure |

Porous granules |

Fine powder |

|

Typical application |

Premium instant coffee |

Commodity-grade instant coffee |

Equipment Considerations for Freeze-Dried Instant Coffee

Industrial freeze drying systems like the BSFD-60 are designed to handle large volumes of coffee extract while maintaining precise control over temperature, pressure, and drying time. Key equipment features often include:

· High-capacity vacuum freeze dryers

· Uniform shelf temperature control

· Efficient vapor condensation systems

· Automated process control for batch consistency

Selecting the right freeze drying equipment directly impacts product quality, energy efficiency, and operational cost.

Conclusion

So, is instant coffee freeze dried?

The answer is: many high-quality instant coffees are. Freeze drying, using equipment such as our BSFD-60 with 600 kg per batch capacity, ensures superior aroma, flavor, and solubility for premium instant coffee products. As demand for higher-quality instant coffee continues to grow, freeze drying remains a cornerstone of modern coffee processing.

If you are considering upgrading your instant coffee production or exploring freeze drying solutions, our team can provide detailed technical guidance, equipment specifications, and turnkey processing support. Contact us today to discuss your requirements and request a personalized consultation.

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

.webp) Swedish

Swedish

Polish

Polish

Basque

Basque

Lao

Lao

Bengali

Bengali

Bulgarian

Bulgarian

.webp)