-

tel: +86 13012879648

-

email: info@jingyitechno.com

Is a Freeze Dryer the Same as a Dehydrator?

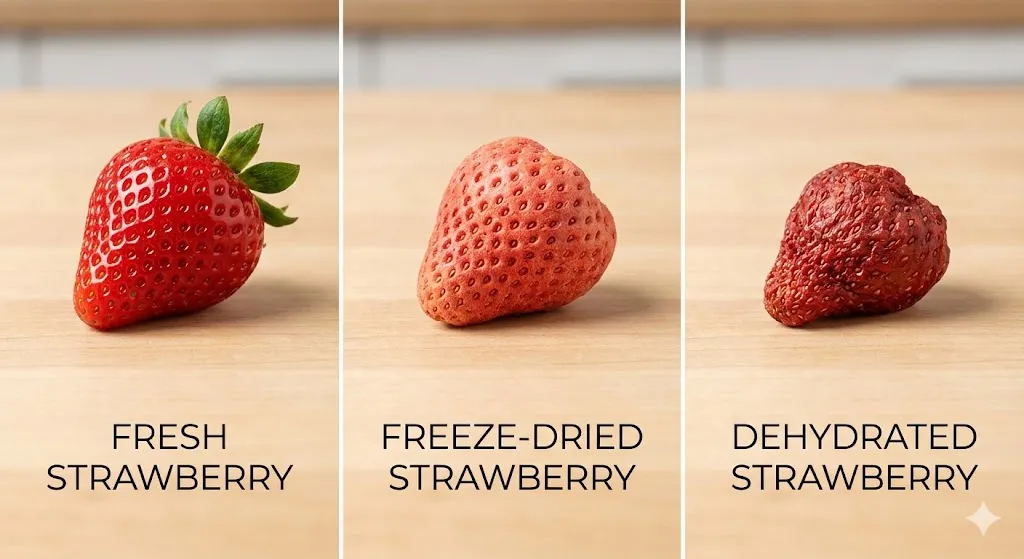

No, a freeze dryer is not the same as a dehydrator. A freeze dryer removes moisture by sublimation under vacuum, while a dehydrator uses heated air to evaporate water. This fundamental difference leads to major variations in product quality, shelf life, nutrient retention, and industrial applications.

Introduction

As demand for long shelf life and high-quality dried products continues to grow, many food processors and manufacturers ask a common question: is a freeze dryer the same as a dehydrator? While both technologies are used to remove moisture, they operate in very different ways and serve different production goals. Understanding these differences is essential when selecting the right drying solution.

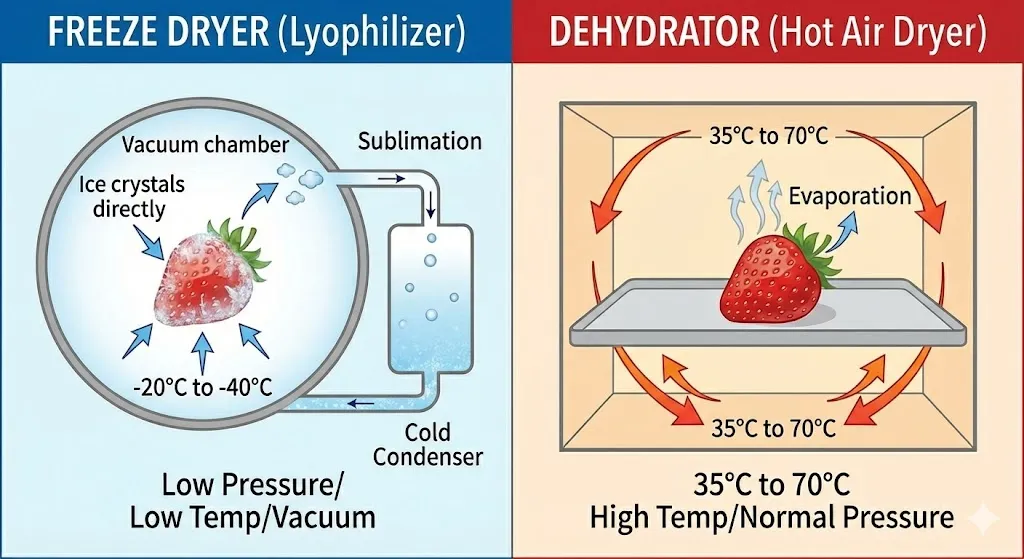

How Does a Freeze Dryer Work?

A freeze dryer works by first freezing the product and then placing it under deep vacuum conditions. Instead of melting into liquid water, the ice inside the product transitions directly into vapor through sublimation. This low-temperature process helps preserve the original structure, flavor, color, and nutritional value of the material.

Freeze drying typically involves three stages:

· Freezing the product to a controlled temperature

· Primary drying, where ice sublimates under vacuum

· Secondary drying, which removes bound moisture for long-term stability

How Does a Dehydrator Work?

A dehydrator removes moisture using circulating hot air. Heat causes water inside the product to evaporate gradually over time. While this method is simpler and more energy-efficient, higher temperatures often lead to shrinkage, texture changes, and nutrient loss.

Dehydration is commonly used for:

· Dried fruits and snacks

· Jerky and pet food

· Low-cost, small-scale food processing

Freeze Dryer vs Dehydrator: Key Differences

|

Feature |

Freeze Dryer |

Dehydrator |

|

Moisture removal method |

Sublimation under vacuum |

Evaporation using heated air |

|

Operating temperature |

Low temperature |

Moderate to high temperature |

|

Product structure |

Maintains original shape and porous structure |

Shrinkage and denser texture |

|

Nutrient retention |

High retention of vitamins and bioactive compounds |

Partial nutrient loss due to heat |

|

Rehydration performance |

Fast and complete rehydration |

Slower and often incomplete |

|

Shelf life |

Several years with proper packaging |

Shorter shelf life |

|

Equipment complexity |

Advanced system with refrigeration, vacuum, and condenser |

Simple mechanical structure |

|

Typical applications |

High-value food, pharmaceuticals, biotechnology |

Snacks, jerky, basic dried foods |

Why the Difference Matters in Industrial Production

In industrial processing, the choice between freeze drying and dehydration directly affects product quality, shelf life, and market positioning. Freeze drying is preferred when product integrity, active ingredients, and premium quality are critical. Dehydration, on the other hand, is more suitable for cost-sensitive products with simpler quality requirements.

From an engineering perspective, freeze dryers require vacuum systems, refrigeration, and precise control, while dehydrators rely primarily on airflow and heating.

When to Use a Freeze Dryer vs a Dehydrator

Choose a freeze dryer when:

· Long shelf life without preservatives is required

· Product shape, color, and texture must be maintained

· Rapid and complete rehydration is important

· Processing pharmaceuticals, nutraceuticals, or premium foods

Choose a dehydrator when:

· Lower equipment and operating costs are a priority

· Some texture and nutrient loss is acceptable

· Producing dried snacks, herbs, or basic food ingredients

People Also Ask

Is freeze drying better than dehydrating?

Freeze drying generally produces higher-quality products with better structure and nutrient retention, but it requires more complex equipment and higher investment.

Can a dehydrator replace a freeze dryer?

No. A dehydrator cannot achieve vacuum conditions or sublimation and therefore cannot replace a freeze dryer for applications that require freeze drying technology.

Why is freeze drying more expensive?

Freeze drying involves longer processing times, vacuum systems, refrigeration, and higher energy consumption, which increase both equipment and operating costs.

What industries use freeze dryers?

Freeze dryers are widely used in food processing, pharmaceuticals, biotechnology, medical research, and specialty ingredient manufacturing.

About Shanghai Jingyi Tech Co., Ltd.

Shanghai Jingyi Tech Co., Ltd. is a high-tech manufacturer specializing in vacuum freeze drying technology. Since 2007, the company has supplied commercial-scale and industrial freeze dryers, as well as turnkey vacuum freeze drying processing lines, to customers worldwide.

With modern manufacturing bases and a pilot-scale freeze drying laboratory, Jingyi Tech supports customers from process development and equipment design to installation, commissioning, and technical training.

Conclusion

A freeze dryer is not the same as a dehydrator. While both remove moisture, they serve different purposes and markets. For manufacturers focused on high-value, stable, and premium products, vacuum freeze drying remains the preferred solution. Understanding these differences helps businesses select the right drying technology for long-term success.

For professional consultation on freeze drying equipment and processing solutions:

· Email: info@jingyitechno.com

· WhatsApp: +86 13012879648

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

.webp) Swedish

Swedish

Polish

Polish

Basque

Basque

Lao

Lao

Bengali

Bengali

Bulgarian

Bulgarian

.webp)