-

tel: +86 13012879648

-

email: info@jingyitechno.com

.webp)

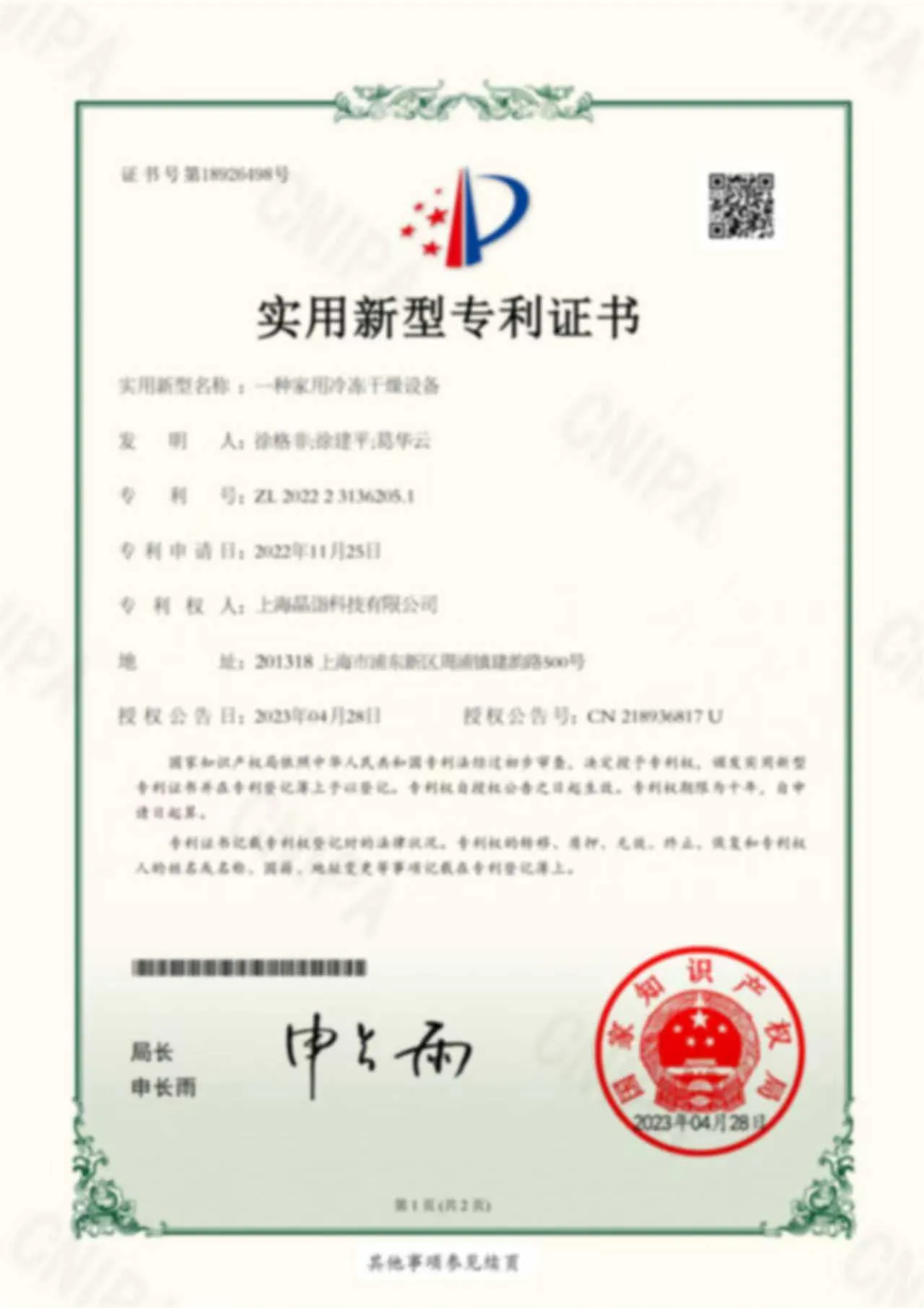

BSFD/BTFD Series Industrial Freeze Dryer Lyophilizer for Food Fruit Vegetable Celery Dried Freeze Drying Machine

Production Scale Vacuum Freeze Dryer is a high-capacity system designed for large-scale production, typically featuring a freeze-drying area of 5 m² or more and handling 50 kg or above per batch. As a large freeze dryer for industrial use, it is widely applied in pharmaceuticals, food processing, biotechnology, and chemical industries, ensuring stable performance and compliance with international standards.

Freeze dryer, also called a lyophilizer, gently removes moisture through low-temperature freezing and vacuum sublimation. It preserves color, nutrients, aroma, and activity, making it ideal for food, pharmaceuticals, biotechnology, herbs, and pet food. We offer household to industrial models for both small-batch research and large-scale production.

①Optional with pre-freezing function, no external pre-freezing storage, to solve the mobile liquefaction of materials and pollution risk.

② The freeze-dried chamber and shelves are made in strict accordance with GMP requirements. The chamber is made of SUS304 grade stainless steel, and the internal is mirror polished.

③ The chamber adopts cold trap integrated design, compact structure, easy to clean, no sanitary dead Angle, and has an observation sight window

④ Cold trap that water catcher using sanitary grade stainless steel SUS304 processing, condensation area is greater than similar products 50%, can shorten the freeze drying time, reduce production costs

⑤ Shelves can be customized according to customer requirements of D31(6363) aluminum alloy material for anodizing treatment or SUS304 stainless steel shelves.

⑥ The refrigeration system are mainly imported brands, with strong refrigeration, fast cooling, stable and reliable perfor-mance.

⑦ According to the material and customer needs to provide a variety of vacuum pump units.

⑧According to the material and customer needs to provide a variety of vacuum pump units.

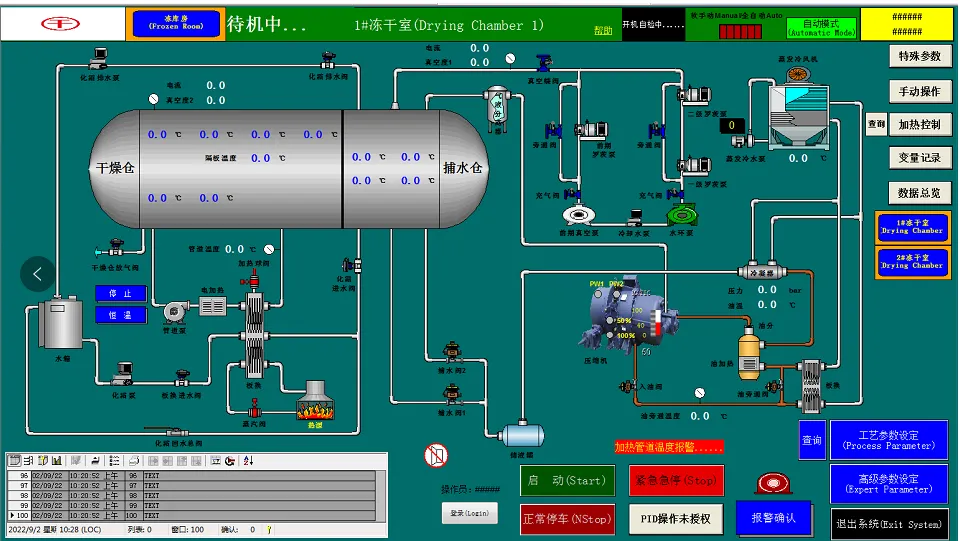

⑨PLC control system adopts Siemens PLC automatic control, simple operation, according to the production process needs to arbitrarily switch control mode and parameter settings, to meet the requirements of different materials freeze-drying process

⑩7-inch real color touch LCD screen, real-time recording display cold trap, material, shelves temperature and vacuum degree, generate drying curve

Compressor

PLC touch screen

Vacuum Pump

| BSFD-5 | BSFD-10 | BSFD-20 | BSFD-30 | BSFD-40 | BSFD-50 | BSFD-60 |

| 5m2 | 10m2 | 20m2 | 30m2 | 40m2 | 50m2 | 63m2 |

| 50Kg/Batch | 100Kg/Batch | 200Kg/Batch | 300Kg/Batch | 400Kg/Batch | 500Kg/Batch | 600Kg/Batch |

| 380V/50hz or Customized | ||||||

| 18.07Kw | 35.1Kw | 51.9Kw | 86.7Kw | 108.7Kw | 138.7Kw | 139Kw |

| 100Kg/Bath | 200Kg/Bath | 400Kg/Bath | 400Kg/Bath | 800Kg/Bath | 1000Kg/Bath | 1200Kg/Bath |

| 800*800*15mm | 1200*800*15mm | 1420*1000*15mm | 1930*1200*15mm | 2100*1200*15mm | 2320*1200*15mm | 3090*1200*15mm |

| Shelf 8+1 layer,Shelf Spacing 80 | Shelf 11+1 layer,Shelf Spacing 80 | Shelf 14+1 layer,Shelf Spacing 80 | Shelf 13+1 layer,Shelf Spacing 80 | Shelf 16+1 layer,Shelf Spacing 80 | Shelf 18+1 layer,Shelf Spacing 80 | Shelf 17+1 layer,Shelf Spacing 80 |

| 395*395*30mm | 395*395*30mm | 470*325*30mm | 480*295*30mm | 520*290*30mm | 460*295*30mm | 510*295*30mm |

| 32Pcs | 66Pcs | 126Pcs | 208Pcs | 256Pcs | 360Pcs | 408Pcs |

| -40~70℃ | -45~70℃ | |||||

| ≤-50℃ | ||||||

| Spray + Immersion | ||||||

| ≤5Pa | ≤10Pa | ≤20Pa | ||||

| Water | ||||||

| Electric or Steam Heating | ||||||

| 8Kw | 16Kw | 24Kw | 28Kw | 32Kw | 32Kw | 32Kw |

| Temperature 5℃~30℃ Relative Humidity <45% | ||||||

| HMI Touch Screen | ||||||

Biotechnology & Research

Floral & Herbal Industry

Food Industry

Pharmaceutical Industry

Our household to industrial freeze dryers can process fruits, vegetables, meats, herbs, pet food, dairy products, coffee, powders, and biological samples. Real cases include freeze-dried strawberries, lemons, limes, dragon fruit, apples, tomatoes, cilantro, chicken breast, and beef—showing stable quality and high nutrient retention across diverse materials and industries.

Freeze-Dried Strawberry

Freeze-Dried Orange

Freeze-Dried Fruits and Vegetables

Freeze-Dried Tomatoes

Freeze-Dried Meat

Freeze Dryer Freeze-Dried

Freeze-Dried Flowers

Freeze-Dried Lime

Our manufacturing strength is built on three large production bases covering 30,000 m², equipped with advanced facilities such as laser cutting machines, CNC bending systems, rolling machines, automated welding equipment, and welding robots. With 137 skilled employees—including 73 senior technicians and 7 engineers—our team has accumulated 17 years of hands-on industry experience and user insights. This strong technical foundation enables powerful OEM/ODM capabilities and full turnkey freeze-drying production line solutions for global customers.

.webp)

We use reliable, long-tested packaging methods to ensure safe delivery of every product. Depending on the machine’s size and weight, we prepare reinforced plywood crates or durable carton boxes with internal supports. Packaging can also be customized according to your requirements, allowing you to choose the format that best suits your shipping needs.

· 18+ Years Experience of Freeze Drying Equipment

· Provide Complete Food Processing Turnkey Solutions

· 3 modern manufacturing bases covering over 30,000 m²

· Promise production & on-time delivery

· CE & ISO quality guarantee

· Offer parts for free if have quality issues

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

.webp) Swedish

Swedish

Polish

Polish

Basque

Basque

Lao

Lao

Bengali

Bengali

Bulgarian

Bulgarian

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)